Author: Admin View: Post Time: 2017 / 05 / 16

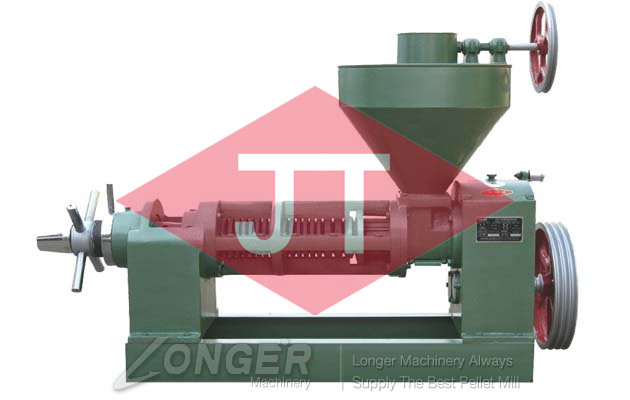

What is the feature and principle of hydraulic oil press?

Hydraulic oil press is mainly used for cold pressed machine, soy bean cake in the protein is not damaged, can be used to make tofu, soy milk, such as bean products, the rest of the slag can be used as feed and fertilizer, its are more widely used.

Hydraulic oil press is composed of two main parts of hydraulic and press machine.

1, hydraulic pump pressure is not enough

The reason:

To be contaminated or in contact with the oil; Return to oil in and out of the oil valve in and out of the oil valve. Small piston and pump wear clearance is too large. The corresponding rule of elimination is that it shall be ground up after it is taken apart. To keep the plug and seat of the oil valve in and out of the mill. Replace the new pump.

2, the hydraulic pump can't pump oil

The reason:

The oil filter is blocked; The oil has been used for a long time, and the sediment is attached to the feed valve, making the accelerator tight. The oil in the tank is too thick or set in cold. A shortage of oil in the tank. No vacuum in the hydraulic pump. The corresponding elimination method is: To renew or release old oil; To filter and clean the oil intake valve, and grind it to make it close. To replace the thin oil, the cold weather should raise room temperature. To add sufficient amount of oil to the tank; Remove the small piston and inject the oil and then press.

The pressure gauge of the hydraulic press can't be maintained, and it is falling fast

The reason is that the relief valve is not sealed; The plug and ball of the oil valve and the steel ball are in bad contact; The tubing joints and hydraulic cylinder screw and hydraulic cylinder are not tight. The three-pass oil valve is not in contact with the steel ball. The corresponding elimination method is: to grind the safety valve to make it close. To grind in and out of the oil valve; Tighten the tubing joint and the hydraulic cylinder. Lapping the oil valve.