Author: Admin View: Post Time: 2016 / 11 / 28

Introduction of jaw crusher

Jaw crusher generally known as jaw broken. By the moving jaw and static jaw jaw plate composed of two crushing chamber, the simulation of animal jaw movement and the completion of the material crushing operation of the crusher. Widely used in mining smelting, building materials, roads, railways, water conservancy and chemical industries in a variety of ore and large pieces of broken materials. The maximum strength of the crushed material is 320Mpa.

Structure Chart of jaw crusher

Jaw crusher mainly consists of fixed jaw plate, movable jaw plate, rack, upper and lower guarding plate,Adjust the seat, moving rods and other components. A good understanding of the internal structure of jaw crusher can jaw crusher during the use and problems can play a very good help.

Working principle of jaw crusher

Moving jaw hanging on the mandrel, can be used for left and right swing. Eccentric shaft rotation, connecting rod reciprocating up and down, driving the two thrust plates also do reciprocating motion, so as to promote moving jaw about reciprocating motion, to achieve crushing and discharge. This crusher with crank double link mechanism, although the moving jaw by a great crushing reaction, and its eccentric shaft and connecting rod is not much, so the industry made more mainframe and medium machine, To break the hard material. In addition, this crusher work, moving jaw on each point of the trajectory is the mandrel as the center of the arc, the radius of the arc is equal to the point to the axis of the distance, the top arc, the bottom arc, Crushing efficiency is low, the crushing ratio is generally 3-6. As the simple trajectory, it is called a simple swing jaw crusher.

Simple pendulum jaw crusher is simple and compact, eccentric shaft and other transmission parts are less force.

Technical parameter of jaw crusher

(mm)

(mm)

(t/h)

(kw)

(mm)

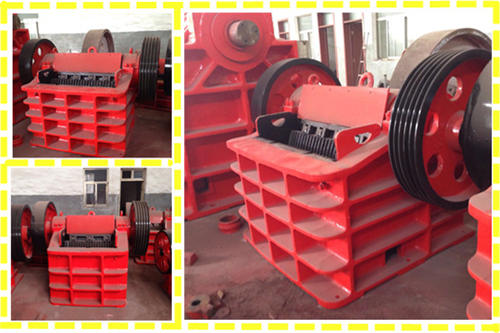

Factory image of jaw crusher

Gongyi Zhanjie Hengtong machinery mainly produce jaw crusher, jaw crusher machine, used jaw crusher, if you are interested in the machine, please contact with me! The email address is hengtongmachinery@yahoo.com.