Author: Admin View: Post Time: 2017 / 06 / 08

How do you deal with the use of peanut oil press machine

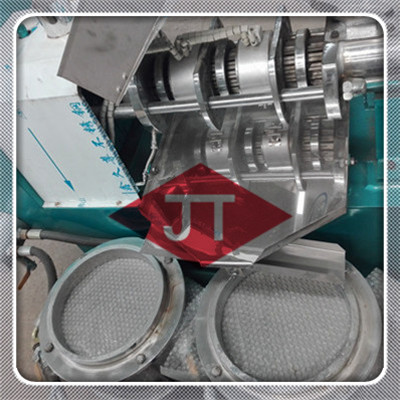

Peanut oil press is the best selling price in our country at present the common equipment, all is the latest model of equipment including model, adopt the most comprehensive of new technology, in the market, the peanut oil press equipment manufacturing industry is the most common is hydraulic spiral, and we all know, the production process is relatively advanced in the present, the use of the squeezing process ensure enough oil material the original nutrients are not lost, also can be a powerful guarantee of yield efficiency, it is better than traditional oil press equipment come a lot, and this equipment can realize multi-usage, sufficient to achieve the high utilization of resources, we squeeze peanut oil press equipment can be used in a variety of materials, at the time of pressing to ensure the material at the most appropriate temperature, we can realize the function of the multi-use of completely.

Analyzing the factors that block the peanut oil press:

1.Sieving oil will be taken unilaterally. If the size of the sieve is not horizontal, the length of the left and right derrick should be adjusted. If there is a torsion in the sieve, the eccentric shaft can be adjusted to make it perpendicular to the frame. If it is to go to stone screen oil, it can adjust the level of the frame. If the air flow is not uniform, adjust the windshield of the bellows, and make the air flow uniformly to the screen. If the net rate is low, a new brush or brush length should be replaced, and the tilt Angle of the flat screen is adjusted.

2, the belt does not lift the oil. The main reason is that the lower part of bucket elevator conveyor oil accumulation is overmuch, cause jams, can open a door, at the bottom of the conveyor of stored oil can be cleared.

The steaming of the pan is not uniform. When inspecting, if the steam drying machine is blocked or corroded, the steam jet should be cleared. If it is in the pan, it can adjust the distance between the blade and the bottom of the pot. If the blade is twisted and worn, the blade should be replaced. If the raw material is not uniform, adjust the limit switch, contact head and float plate, so as to make it coordinate.

3.Roller overload does not turn. The method of elimination is: when the peanut oil press is started, the roll can be removed to adjust the bolt and remove the oil from the roll. If it is too fast to feed, it can shut off the cutting board. If the blank thickness of the mill is not uniform, the nut should be adjusted to adjust the slack and tighten the nut.