Author: Admin View: Post Time: 2016 / 12 / 28

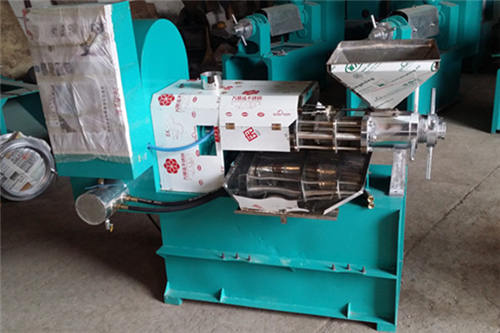

Soybean oil press machine manufacturers how to maintain the small peanut oil press equipment mainly by the electrical control, automatic heating, adjustment, transmission and vacuum filter oil and other components, the screw from the alloy steel by carburizing treatment to enhance the surface hardness and resistance Vacuum, automatic heating and other standard components, the selection of well-known brands, optimize the machine configuration, the machine surface with stainless steel and chrome-plated, in line with the surface grinding machine, grinding machine, grinding machine, grinding machine, Food Hygiene Standard.

Wear parts wear in my factory after the purchase of accessories, such as in other places to buy, may not be due to parts specifications and material differences caused by the damage to the machine, self-service power cord (three-phase four) a number of air switches, By a professional electrician installed and connected to the power supply, the correct connection ground, the method is in the equipment next to the diameter of 10mm reinforced into the ground 1 meter deep, and with the oil press connected to the ground, ancillary equipment, oil press must be fried The oil machine, the roller machine, the oil refining machine and so on the equipment necessary use, if has the need best to clean up machine, the hoisting machine necessary may increase the wearing part service life, the province labor, each place may according to the oil variety and the production scale discretion use .

Press the machine production workshop equipment blockage phenomenon is strictly prohibited during the driving process by hand or steel bar stabbed, only with bamboo or branches, hand Pa must be carried out after the shutdown, the transmission must be protective cover, demolition, After work must be re-installed, oil press production plant to replace the screw in the beat when the beat, to wear protective glasses; usually wear tight overalls to work, female employees to take work cap; press workshop smoking is strictly prohibited for no reason to use open flame.

On the peanut oil press method, practice has proved that, under normal circumstances, the use of "hot pressing" the oil rate and economic benefits are optimized in the "cold pressing method", so as far as possible "hot pressing" Squeeze the law "to increase the number of press, yield reduction, cake residue rate increases, power consumption greatly increased, the economic decline, and the first time in the second press, the bucket and easy to overhead, affecting the feed operation Trouble, poor efficiency.